Welcome to our blog at Kunes Auto Group! Today, let's take a deeper look at how Vantage Mobility International (VMI) transforms regular vans into amazing wheelchair-accessible vehicles. At VMI, they don't just make vans; they create a way for everyone to travel easily and safely.

Understanding the Process

Creating a wheelchair-accessible van is not just about taking out seats and adding ramps. It's a careful process where the whole bottom of the van is changed. VMI uses new parts to make sure people in wheelchairs can move around easily inside the van.

Step 1: Taking the Van Apart

First, a team of experts takes apart the van. They remove things like seats, carpets, and wires. They save as many parts as they can to use again later.

Step 2: Working on the Floor

Next, they take out the original floor and put in a new, lower one. This is really important for making enough room for wheelchairs, so that the drivers can have a great experience while they're on the road. The new floor is made of strong, galvanized, steel that doesn't rust easily, so the van stays in good shape for a long time.

Step 3: Added Protection

Once the new floor has been installed, a fresh protective undercoat is applied to the undercarriage to prevent damage from debris, rust, and help minimize sound while driving on the road.

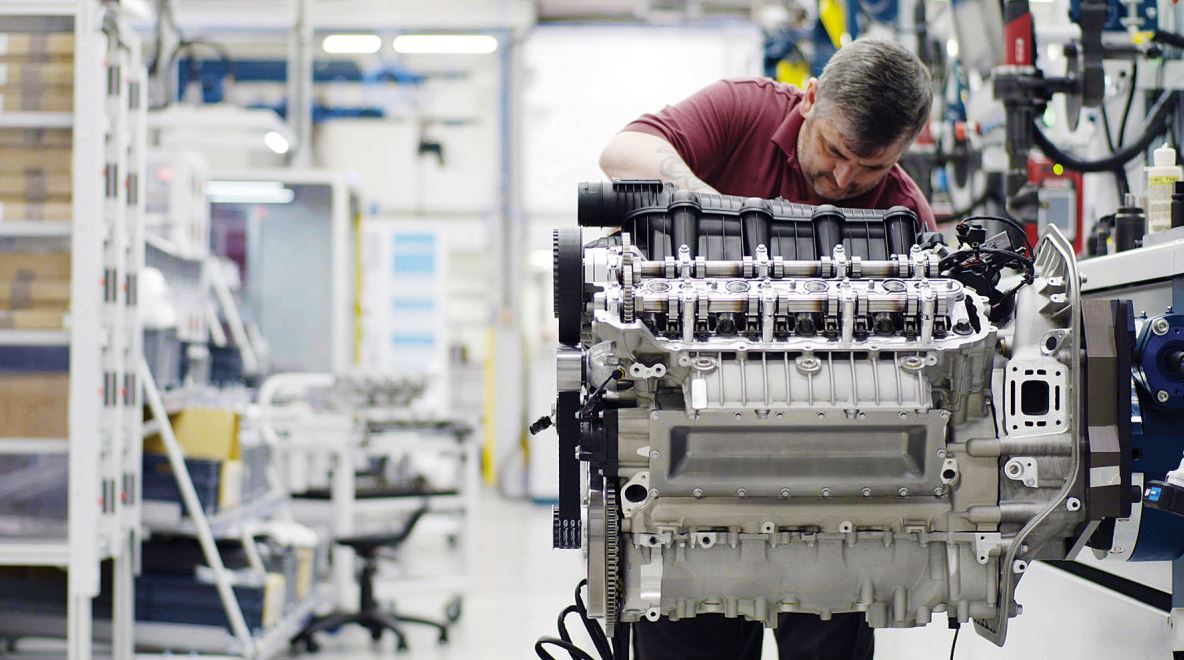

Step 4: Mount the Powertrain and Suspension

VMI ensures the powertrain and suspension are tailored and installed to align perfectly with the van's newly designed floor. This innovative approach in powertrain design was crucial in developing the four-wheel drive mobility van, utilizing the Toyota Sienna.

Step 5: Painting

The expert technicians at VMI make sure the van looks great, painting any new parts to match the rest of the van seamlessly. As they paint over the vehicle, they inspect every inch to make sure all surfaces are covered.

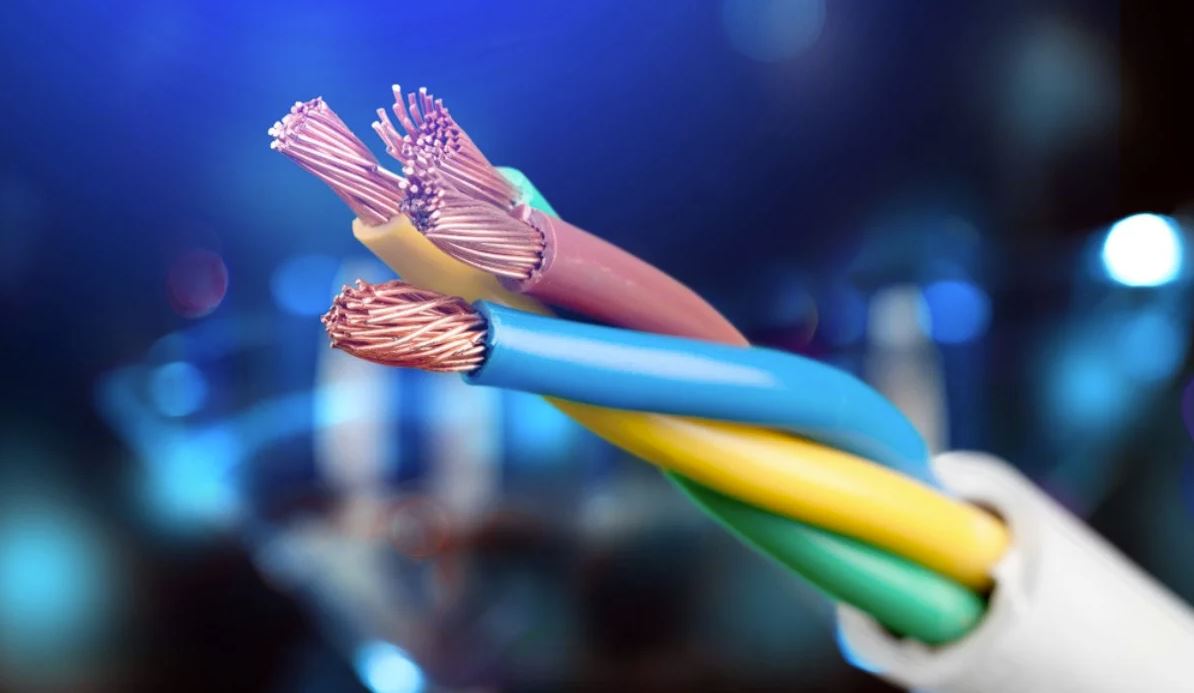

Step 6: Electrical Work

The addition of electrical components is a key step, enhancing the van with new, user-friendly functions. This step involves reattaching the van's current electrical components and adding new features to its electrical and computer systems. These updates allow for easy control using either a separate remote or a key fob that's part of the car keys.

Expert techs make sure to install and check all of the electrical parts carefully. They do this to make sure everything works correctly and the car is safe, easy to use, and comfy. This expert electrical work is really important for upgrading fancy cars, especially newer hybrids like the latest Toyota Sienna, with high-tech features.

Step 7: Final Touches

The last step is putting everything back together. This is when they add features used every day, like adapted seats and ramps. They try to keep the van looking and feeling like it did before, but now it's ready for a wheelchair!

Advanced Features

VMI is always thinking of new ideas. They even made the first all-wheel-drive wheelchair van using the Toyota Sienna. This gives drivers more control and safety.

Safety First

Safety is a big deal at VMI. All their wheelchair vans are tested to ensure that they are NHTSA (National Highway Traffic Safety Administration) approved . They also add a special coat under the van to protect it from things like rust and to make it quieter.

Quality Check

Before a van is finished, it goes through a lot of checks. VMI makes sure everything is perfect, from how it drives to how it looks.

VMI cares a lot about quality, safety, and making sure their vans are the best for people in wheelchairs. We at Kunes Auto Group are proud to share how VMI works to meet your unique needs and go beyond your expectations.

Interested in a wheelchair-accessible van? Browse our selection of Mobility Vans below!